Get Quote

RECOMMENDED PRODUCTS

COMPANY PROFILE

Contact Supplier

Shenzhen city Xicheng Plastic Co., Ltd. Located in Bao an District, Shenzhen, The company mainly produces waste gas treatment equipment, ventilation equipment, exhaust tower, activated carbon tower, washing tower, PP board, PP pipe, PP wind valve, PP elbow, and other ventilation accessories. Our company can be customized according to the drawings or requirements of the processing. Product quality assurance, price concessions.

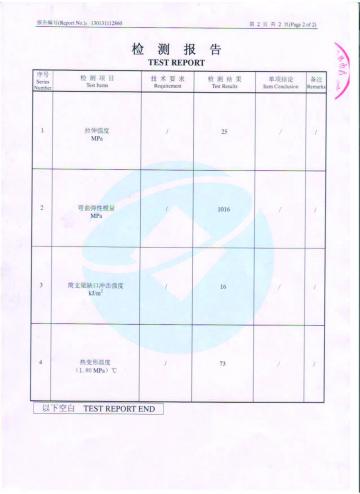

CERTIFICATES

Email to this supplier